Engine operation precautions

Before starting the engine

• The intake system, fuel system, lubrication system and cooling system must be inspected;

• Relevant circuits, the aftertreatment system and the alarm light also need to be checked.

After the engine is started

• Idling at least 3-5 minutes to ensure proper lubrication;

• Do not keep the engine running at idle speed for more than 10 minutes .

When starting the engine

• The hydraulic system operating handle or gearbox should be placed in neutral gear;

• Do not step on the gas pedal;

• Turn the key to the "ON" position and wait for the "WAIT-TO-START" indicator to go out before starting the engine;

• The motor starting time must not exceed 30 seconds, and the interval for next start should be 2 minutes;

• If there is an existing fault code, the problem should be solved before starting the engine;

• If the vehicle cannot be started for three times, check the electronic control system and the fuel system;

• If the vehicle still has no oil pressure for 15 seconds after the engine is started, turn off the engine immediately and check the lubrication system.

After the engine is running at full load

• Shut down the vehicle after 3-5 minutes of idling;

• When shutting down the engine, cut off the power after keeping the key at the “ON” position for at least 30 seconds. (please strictly follow this step for China IV engine, otherwise it may cause damage to the aftertreatment system);

• Do not flush the engine with water.

Daily inspection and maintenance of SCR aftertreatment system

Daily inspection and maintenance of the after-treatment system can avoid the OBD failure in the aftertreatment system, reduce maintenance cost, and improve operational efficiency.

Inspection

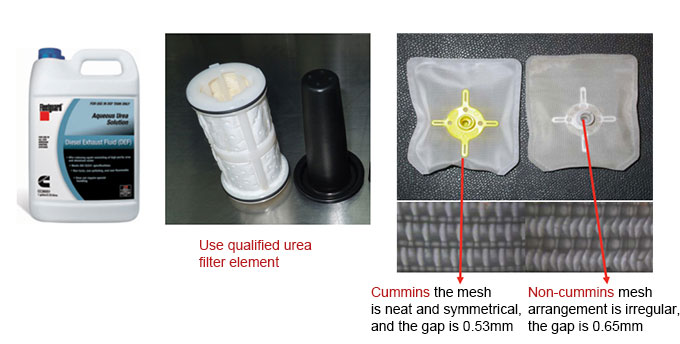

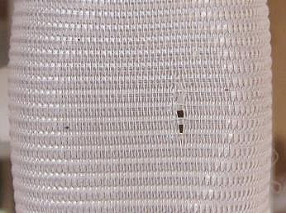

• Check the urea tank level every day and add urea in time; check if the filter mesh and pipeline in the urea pump is intact and if there is blockage (maintenance mileage 100,000 km).

Precautions

• It is strictly forbidden to prepare urea solution privately; Please use qualified fuel and urea products;

• The main power switch can be turned off 1 minute after the engine is stopped to ensure the emptying of the aftertreatment system.

• Poor quality of the urea solution, low liquid level, damaged filter, and plugging will cause damage to the urea pump, OBD failure, and engine power reduction.

• Non-standard inlet and outlet piping arrangements will cause urea to remain in the pipeline, which can easily lead to crystallization of urea. In cold temperature conditions, ice will also cause blockage of the pipeline, resulting in damage to the urea pump, OBD failure, and engine power reduction.

Maintenance of the aftertreatment system for China IV electronic control engine

Daily inspection and maintenance of electrical system

Inspection

• Check the liquid level of the battery regularly and add liquid in time;

• Check if there is corrosion or looseness at the battery terminals every day; check the wiring harness of the vehicle and the electrical components to ensure good contact and no aging.

• Keep the wiring harness and the connecting parts of the electrical components dry and clean. Wipe with a clean and soft cloth. Do not flush the engine assembly with water.

• If the electrical system is accidentally flooded, remember to first cut off the main switch of the battery and immediately notify the maintenance personnel to handle it. And do not run the engine by yourself;

• It is strictly forbidden to connect wire or repair on the vehicle by yourself, and replacement of spare parts should be conducted by professional service technicians.

Precautions:

Corrosion and looseness of electrical component joints and loose connection of wiring harness will cause difficulty in engine starting, black smoke, OBD failure in the aftertreatment sysem, power reduction and flameout.

Daily inspection and maintenance of the fuel system

Inspection

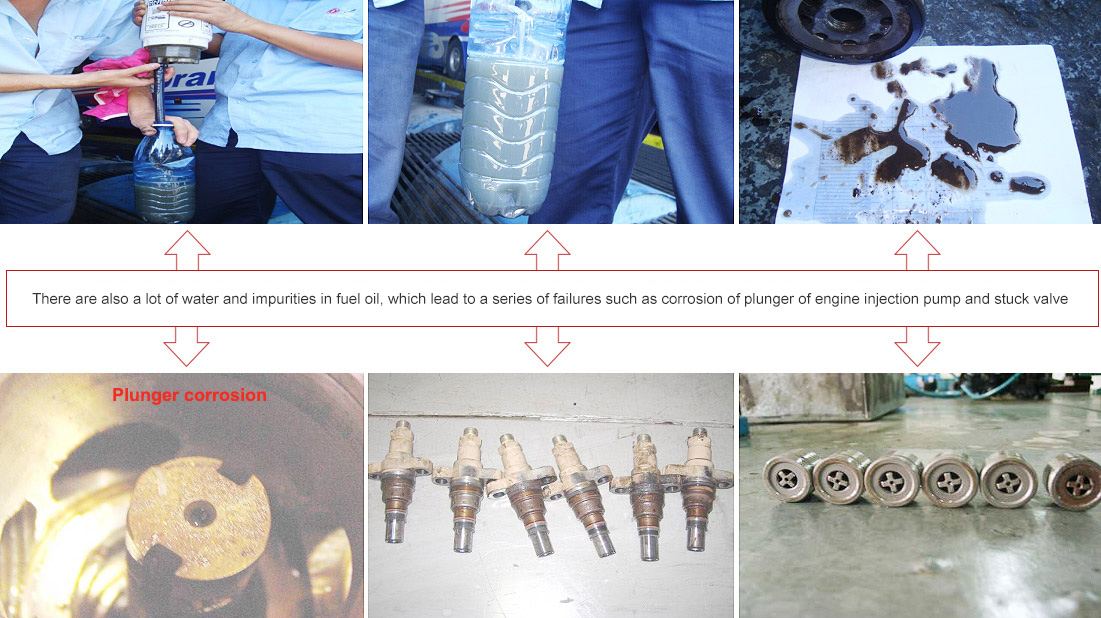

• Check the fuel line for bends, looseness, cracks and leaks;

• Check and drain the water from the fuel pre-filter and the oil-water separator every day;

• Use clean fuel up to standard; replace the fuel filter during the maintenance cycle.

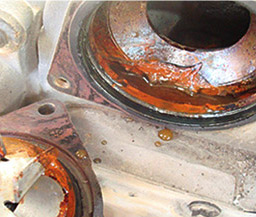

Precautions:

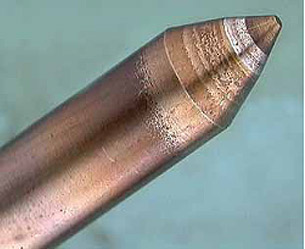

Fuel with water content

If the fuel quality is not up to standard, the fuel filter is not regularly replaced, and the fuel that enters the engine contains water, it will cause internal wear of the high pressure fuel pump, rusted plunger, blockage of the plunger and fuel outlet valve, injector corrosion, blockage of pin valve, and emission not up to the standard, increased repair cost, shorter engine life, etc.

Daily inspection and maintenance of intake and exhaust systems

Inspection

• Check the sealing of the intake and exhaust lines to see if there is any cracking, loose clamps, leaking or blockage;

• Check the intercooler for cracks, holes or other damages;

• Check the engine breathing tube for cracks, damage, or any mud, debris or ice in the tube;

• Clean and replace the air filter regularly to ensure clean air enters the engine.

Precautions

Blockage, leakage, and pollution of the intake system can cause emitting of black smoke, power reduction, early wear, and oil entering the combustion chamber, which will increase engine maintenance cost and reduce engine life.

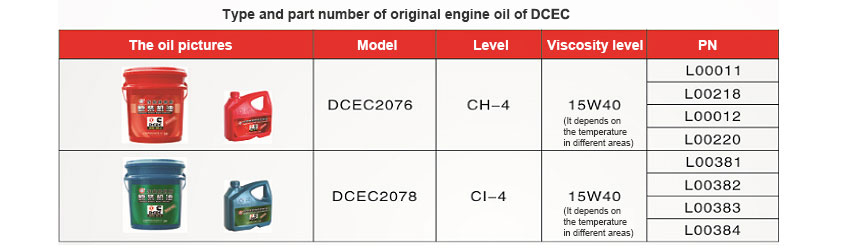

Daily inspection and maintenance of the lubrication system

Inspection and maintenance

• Check the oil level and oil quality daily and check if there is oil leakage;

• Change the oil and oil filter timely in the maintenance cycle; use DCEC specified oil and oil filter.

Precautions

Inferior oil and filters can cause wear and tear on the engine's lubricating parts (scuffing of cylinder bore, bearing score, and even engine scrap), which leads to higher engine maintenance costs and shorter engine life.

Daily inspection and maintenance of the cooling system

Inspection and maintenance

• Long-acting organic coolant shall be used for the engine;

• Check the coolant level every day, and check the tank for blockage, cracks, breakage, or leakage in the pipeline;

• Check the tension of the drive belt and check for cracks; visually inspect the cooling fan for cracks, loose rivets, and bent or loose blades. Check the fan and make sure it is securely installed;

Precautions

If not using engine coolant or using improper coolant, it will cause rust and blockage of the engine water jacket, high temperature of engine, power drop, cavitation corrosion of cylinder liner, etc, resulting in increased maintenance costs and reduced engine life.